- High shear homogenizer

- Speed Range:10000-31000rpm

- Processing Capacity: 0.2ml~7000ml (H2O)

- Viscosity: 5,000cP

- Speed Display: Graduate display, LCD display

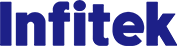

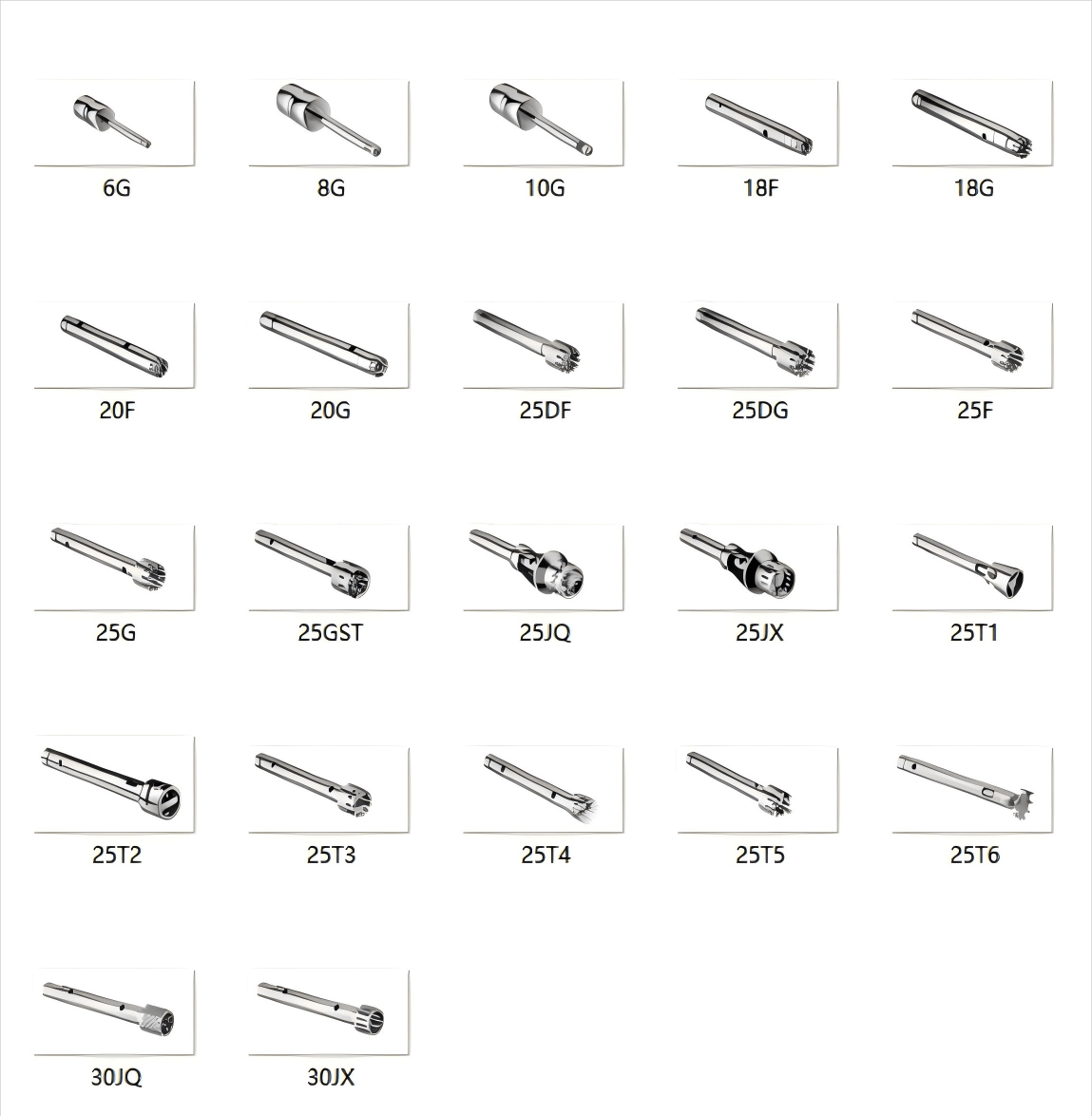

Homogenizer, HMG-500C, HMG-500D

Description

Application

It’s mainly used in industries such as pharmaceuticals, biochemistry, food, nanomaterials, coatings, adhesives, daily chemicals, printing and dyeing, petrochemicals, paper chemistry, polyurethane, inorganic salts, silicone, asphalt, pesticides, water treatment, heavy oil emulsification, etc.

Features

Convenient & Stable Performance

- Equipped with a high-quality motor, it ensures smoother operation, lower noise, and supports extended running times.

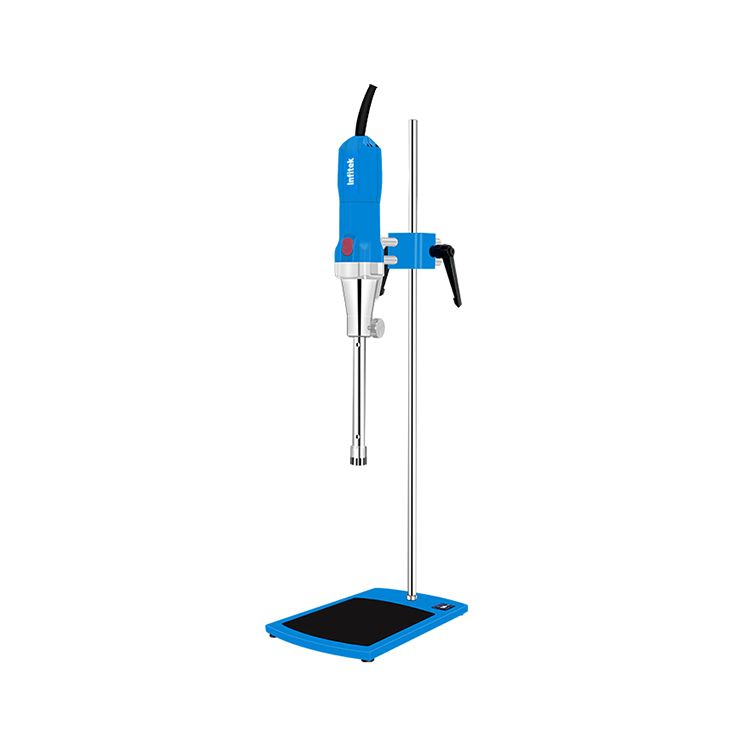

- A variety of interchangeable work heads are available to meet demanding dispersion, emulsification, and homogenization experimental requirements.

High-Efficiency Shearing & Precise Processing

- With a rotational speed of up to 31,000 rpm and compatible with over 20 work heads.

- The high-speed rotor combined with the precision stator chamber generates intense hydraulic shearing, centrifugal extrusion, and high-speed impact/collision. This thoroughly disperses, emulsifies, homogenizes, pulverizes, and mixes materials, ultimately yielding a stable, high-quality product.

High-Performance Motor & Robust Design

- Equipped with a premium motor for stable operation, lower noise, and extended running times.

- Features a safe and reliable design.

Premium Corrosion-Resistant Materials

- All material-contact parts of the work head are constructed from high-quality stainless steel, offering good corrosion resistance.

Quick-Release Coupling for Easy Maintenance

- The work head connects to the drive motor via a coupling, enabling quick and easy disassembly and assembly.

Stepless Speed Control for Precision

- Adopt stepless speed controller, precise speed regulation and stable operation.

Specification

| Model | HMG-500C | HMG-500D |

| Speed Range | 10000-31000rpm | 10000-31000rpm |

| Processing Capacity | 0.2ml~7000ml (H2O) | 0.2ml~7000ml (H2O) |

| Standard Working Head | 25G | 25G |

| Max. Viscosity | 5,000cP | 5,000cP |

| Speed Display | Graduate display | LCD display |

| Speed Control | Stepless Regulation | Stepless Regulation |

| Material-Contact Parts | 316L Stainless steel | 316L Stainless steel |

| Immersion Shaft Sleeve | PTFE | PTFE |

| Operating Temperature | ≤120℃ | ≤120℃ |

| Ambient Temperature Range | 5~40℃ | 5~40℃ |

| Max. Relative Humidity | 80% | 80% |

| Process Type | Batch processing | Batch processing |

| Electricity | 220V, 50/60Hz | 220V, 50/60Hz |

| Input Power | 500W | 500W |

| Host Net Weight (excl. working head) | 3 kg | 3 kg |

| Host Gross Weight | 3.7kg | 4 kg |

| Host Dimensions (L × Ø) | 275*65 mm | 275*65 mm |

When used with compatible blade heads, the parameters will not exceed the machine’s specified limits: a maximum processing capacity of 7,000 mL (H2O) and a maximum viscosity of 5,000 cP.

| Specification | Processing Capacity (ml) | Viscosity (cP) | Stator Diameter (mm) | Linear Speed(m/s) | Material | Functional Description |

| 6G | 0.2-10 | 100 | 6 | 6 | 316 | Suitable for dispersion, fragmentation, homogenization of animal and plant tissues. |

| 8G | 1-60 | 100 | 8 | 8 | 316 | |

| 10G | 10-150 | 200 | 10 | 10 | 316 | |

| 18G | 50-1500 | 3000 | 18 | 19 | 316 | Suitable for solid-liquid mixing, oil-water emulsification, cream preparation, emulsion polymerization, silicone oil emulsification, homogenization, etc. in medium-high viscosity systems. |

| 18F | 100-1500 | 2000 | 18 | 19 | 316 | Suitable for solid-liquid mixing, oil-water emulsification, cream preparation, emulsion polymerization, silicone oil emulsification, homogenization, etc. in medium-low viscosity systems. |

| 20G | 50-1500 | 3000 | 20 | 19 | 316 | Suitable for solid-liquid mixing, oil-water emulsification, cream preparation, emulsion polymerization, silicone oil emulsification, homogenization, etc. in medium-high viscosity systems. |

| 20F | 50-1500 | 3000 | 20 | 19 | 316 | |

| 25GST | 100-5000 | 5000 | 25 | 27 | 316 | |

| 25G | 100-5000 | 5000 | 25 | 27 | 316 | |

| 25F | 100-5000 | 5000 | 25 | 27 | 316 | Suitable for solid-liquid mixing, oil-water emulsification, cream preparation, emulsion polymerization, silicone oil emulsification, homogenization, etc. in medium-low viscosity systems. |

| 25DG | 100-5000 | 5000 | 25 | 27 | 316 | Suitable for solid-liquid mixing, oil-water emulsification, cream preparation, emulsion polymerization, silicone oil emulsification, homogenization, etc. under vacuum and pressurized environments. |

| 25DF | 100-5000 | 5000 | 25 | 27 | 316 | |

| 25JX | 100-5000 | 8000 | 25 | 35 | 316 | Vertical convection shear mixing, suitable for medium-shear dispersion and solid/liquid mixing. |

| 25JQ | 100-5000 | 8000 | 25 | 35 | 316 | |

| 25T1 | 100-5000 | 8000 | 25 | 27 | 316 | Rapid liquid-liquid mixing and dissolution of suspended powders in medium viscosity systems. |

| 25T2 | 100-5000 | 5000 | 25 | 27 | 316 | |

| 25T3 | 100-5000 | 5000 | 25 | 27 | 316 | Solid/liquid dispersion mixing, suitable for wet grinding, effectively reducing material size and increasing uniformity. |

| 25T4 | 100-5000 | 5000 | 25 | 27 | 316 | Ultra-strong dispersion and tissue disruption, suitable for pulverization, homogenization, dispersion, and shearing of animal and plant tissues. |

| 25T5 | 100-5000 | 5000 | 25 | 27 | 316 | Suitable for dispersion and homogenization in medium-high viscosity systems. |

| 25T6 | 100-5000 | 5000 | 25 | 27 | 316 | Ultra-high-speed stirring, suitable for dissolution and dispersion in medium-high viscosity systems. |

| 30JX | 250-10000 | 15000 | 30 | 47 | 316 | Suitable for paste, fibrous materials, liquids. |

| 30JQ | 250-8000 | 15000 | 30 | 47 | 316 |

Get Social